Moisture is the Enemy: Navigating the Challenges of Round Module Pickers in Cotton Picking

The rapid adoption and influx of Round Module Pickers into Australia has changed the picking operation landscape. These machines, celebrated for their enhancements in cleanliness, labour and efficiency savings have become a vital asset to growers. However, with these advancements come new challenges, particularly in managing moisture levels to ensure the quality of the cotton crop.

The Promise and Perils of Technological Advancement

Round Module Pickers with their enhanced horsepower, traction and fan capacity, have made it possible to harvest cotton under conditions that would have previously halted operations. This capability, however, tempts operators to test the limits of moisture levels, picking too early in the morning, too late into the night, or before the crop has reached ideal defoliation or maturity. Just because the picker can physically go up and down the field does not mean it should. During these critical times, the pressure mounts for growers who manage large machinery, a ripening crop, and the daily management of their farms. This pressure can lead to:

- An increased eagerness to harvest as quickly as possible to avoid impending rainfall.

- A bottleneck effect in harvesting schedules, with many fields becoming ready simultaneously.

- Elevated moisture levels in the cotton lint, posing risks to quality.

- Humid conditions conducive to dew formation in the evening.

- A scenario where the management of cotton regrowth becomes necessary.

Quality at Risk

It is essential to remember that solving one problem should not lead to the creation of another. Issues such as spindle twist, damage to the picking head, and harvesting cotton with a moisture content above 12% can significantly degrade fibre quality. High moisture levels increase the risk of yellowing or spotting from fungal contamination, as microbial activity flourishes in moist, warm conditions. Moisture content above 13% markedly accelerates the yellowing process, which can continue even after the temperature of the module drops. Seed cotton harvested with more than 16% moisture content faces inevitable quality losses, even if it is ginned immediately.

Conversely, seed cotton with less than 12% moisture can usually be stored for extended periods without significant quality loss. Green leaf and damp seed usually raise the seed cotton moisture content above 12%. It is essential to accurately assess the moisture content of the lint and seed before commencing each day’s harvest.

Strategies for Moisture Management

Effective moisture management is critical. Recommendations include:

- Installing moisture measuring equipment on the picker or using handheld moisture meters.

- Utilising moisture measuring equipment should be calibrated yearly to ensure correct readings. (Note: Handheld moisture meters are usually +/- 1% accurate.)

- A hard seed when bitten indicates a brittle seed coat and moisture below 12%. (Note: This method is less accurate than the handheld moisture meter)

- When a handful of cotton collected in the palm of your hand is squeezed into a ball and then released, the moisture content is right if the seed cotton springs back to near its original size.

Moreover, excessive green plant material can stain the cotton during storage and requires ginners to use heat, which can damage fibre quality.

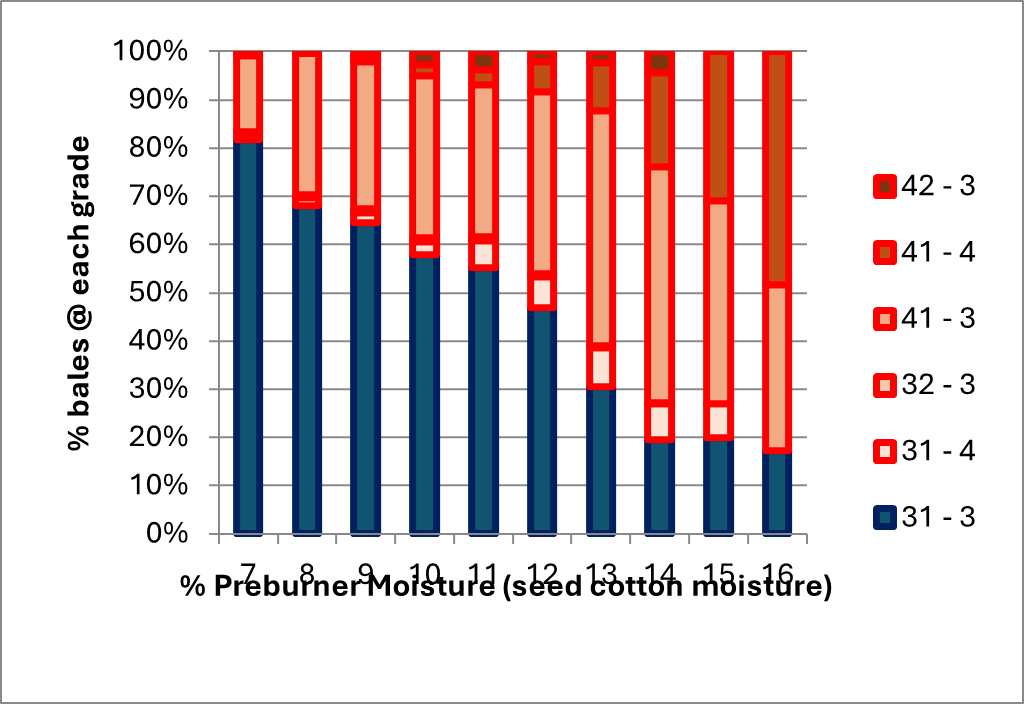

Figure 1: Cotton grade and pre-burner moisture Percentage. (Cotton Aust.)

Figure 1 represents approximately 13,000 bales from traditional and round modules at one gin with pre-burner moisture monitoring equipment. Each column represents the proportion of bales by grade at each moisture percentage. Although moisture content is not the only determinant of colour and leaf grade it is clear that high moisture content can have an additional negative impact on fibre quality.

Additionally, fibre properties such as micronaire, length, strength, and elongation are at risk. Seed cotton moisture not only affects fibre quality but also seed quality, decreasing germination and vigour, due to an increase in free fatty acid content and aflatoxin levels. High moisture content also increases mechanical damage to seeds, resulting in an increase in the quantity and weight of the seed coat fragments and mote. During ginning, increased moisture levels can lead to increase gas usage, a reduction in production, blockages and the possibility of fires.

Frequent moisture monitoring, especially at the end of each day, is essential due to rapid changes in moisture levels. For example moisture can increase from 4% to 6% within 10 minutes as night and dew point temperature fall rapidly.

The Impact of Round Module Characteristics

The unique characteristics of round modules highlight the need to continually monitor seed cotton moisture including:

- Compact Design: Round modules, weighing up to 2.6 tons and producing 4-4.2 bales, in comparison to the conventional 12 to 16-ton module, which produces 22-28 bales.

- Plastic Wrapping: The plastic encasement of round modules are very compact restricting moisture evaporation as there is less surface area exposed to the air to allow for moisture to evaporate.

- Moisture Levels: There will be less dilution of the cotton from across different picking times and moistures. The last round picked at night will have significantly higher moisture than those picked in the heat of the day.

- Ginning Efficiency: From a ginner perspective, this is an issue as they are unable to respond to rapidly changing moisture levels to gin efficiently and cleanly.

- Storage Considerations: Potential extended storage periods in fields or gin yards necessitate careful module placement to ensure adequate air circulation and moisture evaporation.

- Isolation Challenges: High moisture modules are difficult to isolate for express ginning, complicating logistics and potentially affecting overall ginning efficiency.

Influencing Factors on Module Moisture

Effective moisture management hinges on understanding and addressing factors that influence module moisture content:

- Defoliation: Proper defoliation is paramount, reducing the green leaf content and, consequently, the moisture added to the module.

- Picking Times: Picking should align with suitable conditions to avoid excess moisture. Issues arise when picking is recommenced too soon after rainfall events, or is pushed into the night after dews have settled in. Pushing the limits in the morning is less of a risk as the cotton is drying.

- Tarping Practices: Innovations in module wrapping reduce the risks associated with traditional tarping but vigilance is still required to prevent moisture ingress through any breaches. Ensure that modules are staged correctly to allow for evaporation air flow and water runoff.

Optimal Moisture Levels for Quality and Efficiency

Aiming for a moisture content of 6-10% is ideal. Within this range, the transport of moisture to the gin yard is minimised, and less heat is required during the ginning process, preserving fibre length and quality. Conversely, modules exceeding 12% moisture demand more intensive ginning efforts, reduce efficiency and elevate fire risks. High moisture levels can lead to microbial degradation of the fibre, affecting colour, strength and overall quality.

In conclusion, the adoption of Round Module Pickers in Australia’s cotton industry has brought efficiency and cleanliness but also highlighted the critical issue of moisture management. Ensuring cotton is harvested with less than 12% moisture content is paramount to maintaining quality, preventing degradation, and avoiding losses. Effective moisture control, through methods like precise moisture measurement and mindful harvesting practices, is essential. Adhering to optimal moisture levels not only preserves the integrity of the cotton but also enhances ginning efficiency and overall crop value. Ultimately, combating moisture is key to leveraging the full potential of Round Module Pickers and securing the high quality of Australia’s cotton crop.