Defoliation Management

A good defoliation is a key part in optimising yield, ensuring quality parameters are met whist improving picking efficiencies.

- There are several ways of determining when it is the best time to apply defoliants which are:

- Cutting the boll open: cutting open the highest harvestable boll and checking seed maturity. This is the most reliable technique.

- Nodes Above Cracked Boll (NACB): the aim is to defoliate at four NACB.

- Percentage open boll: 60% boll opening, being the traditional level.

THERE ARE SOME KEY ISSUES FOR USE OF DEFOLIANTS:

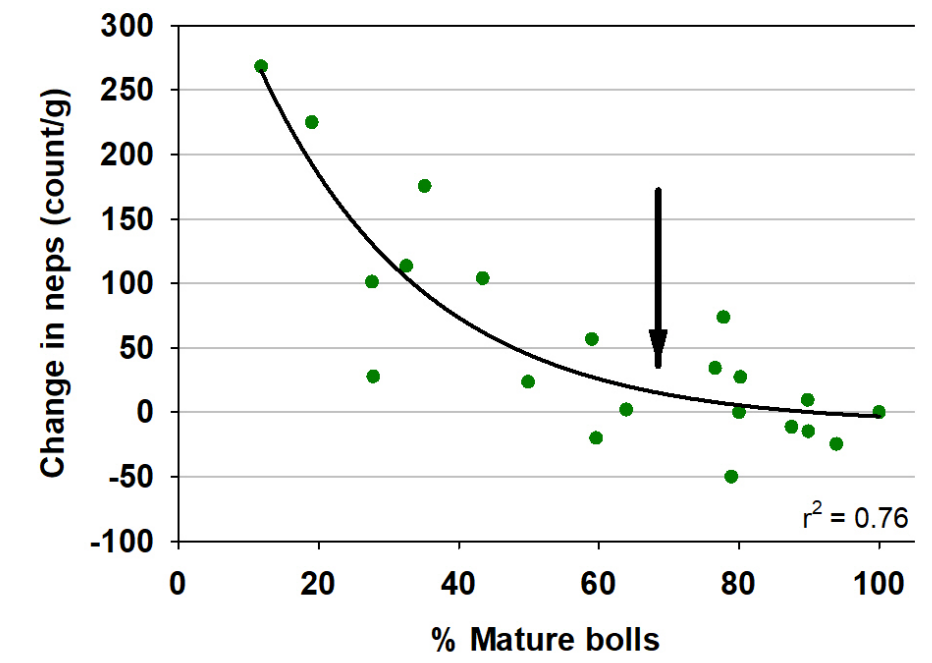

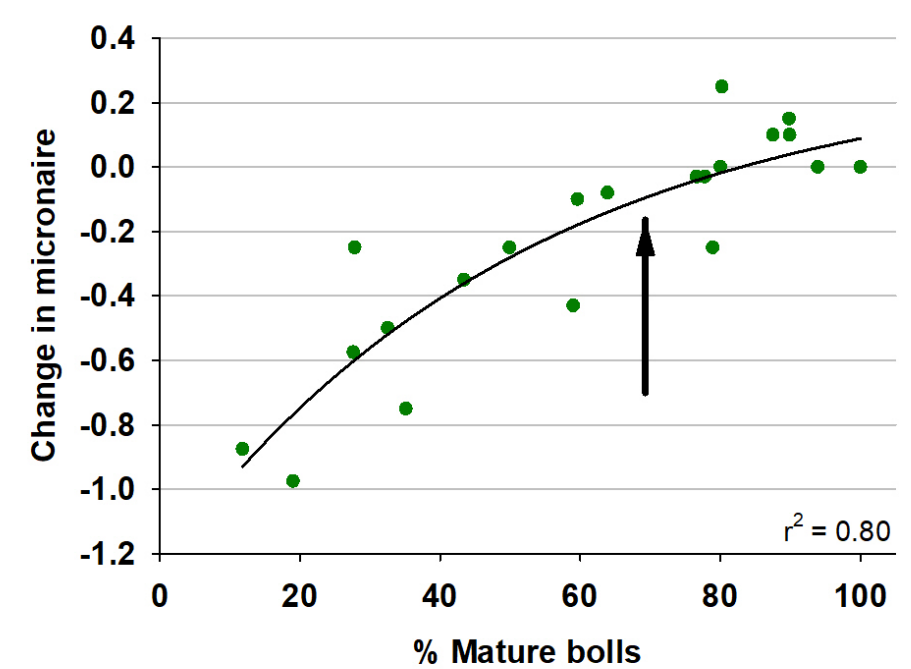

- Boll maturity – if boll openers/conditioners are applied prior to 70% boll maturation they may cause bolls to shed and reduce yield and increase in the incidence of neps.

- Defoliate before the onset of frost. Frost can cause damage to the abscission zone, making defoliants ineffective.

- Defoliation should be timed in with picker availability and picking capacity.

- The plant’s nutrient supply, especially nitrogen, should be exhausted.

- Avoid application of defoliants if rain or cloudy weather is forecast within 3 days of application. Defoliants are taken up slowly by the leaves and will wash off in rain, resulting in an incomplete defoliation. Rain after applying a boll conditioner may hinder boll opening, resulting in ‘tight lock’.

Figure 1: Appearance of cut bolls and seed maturity

Rate and Chemical Selection Issues

A good defoliation is a key part in optimising yield, ensuring quality parameters are met whist improving picking efficiencies. There are several ways of determining when it is the best time to apply defoliants which are:

- Cutting the boll open: cutting open the highest harvestable boll and checking seed maturity. This is the most reliable technique.

- Nodes Above Cracked Boll (NACB): the aim is to defoliate at four NACB.

- Percentage open boll: 60% boll opening, being the traditional level.

THERE ARE SOME KEY ISSUES FOR USE OF DEFOLIANTS:

- Boll maturity – if boll openers/conditioners are applied prior to 70% boll maturation they may cause bolls to shed and reduce yield and increase in the incidence of neps.

- Defoliate before the onset of frost. Frost can cause damage to the abscission zone, making defoliants ineffective.

- Defoliation should be timed in with picker availability and picking capacity.

- The plant’s nutrient supply, especially nitrogen, should be exhausted.

- Avoid application of defoliants if rain or cloudy weather is forecast within 3 days of application. Defoliants are taken up slowly by the leaves and will wash off in rain, resulting in an incomplete defoliation. Rain after applying a boll conditioner may hinder boll opening, resulting in ‘tight lock’. Hormonal defoliants and boll conditioners work at an optimal maximum temperature of 30-35 degrees, and a minimum night time temperature no lower than 12 degrees.

- Cooler temperatures require higher rates.

- Hot temperatures during the growing season can impair the abscission layer of the leaf and increase waxiness, which will cause poor leaf drop and the defoliant to be inefficient.

- Low humidity and water stress can increase the waxiness and thickness of the leaf cuticle reducing chemical uptake.

- The effects of a defoliant can usually be seen 7-10 days after application.

Application Issues

Low humidity decreases uptake as chemicals dry rapidly on the leaf.

In crops with a dense canopy, 2-3 applications may be required.

If increased waxiness of the leaves is suspected, apply the defoliant when the crop is mature and in warmer conditions when the waxy layer is more pliable.

A POOR DEFOLIATION CAN RESULT IN:

- Increased picking moisture.

- Increased leaf grade penalties.

- Decreased picking efficiency.

- Low micronaire: when timed incorrectly, in cooler regions or seasons, if low micronaire is a concern then postponing defoliation will extra time to mature late bolls.

- Increased Neps: when timed incorrectly, small knots of entangled immature or dead fibres that disrupt the spinning processes and damage both yarn and fabric appearance.

Figure 2: Impact of time of defoliation on micronaire and neps. Defoliation when there is less than 70% mature bolls can lower micronaire (resulting in reduced fibre maturity) and increase neps (fibre entanglements). (Adapted from Bange et al. 2009).

© Cotton Seed Distributors Ltd 2022. General guide only; not comprehensive or specific technical advice. Circumstances vary from farm to farm. To the fullest extent permitted by law, CSD expressly disclaims all liability for any loss or damage arising from reliance upon any information, statement or opinion in this document or from any errors or omissions in this document. Roundup Ready Flex®, Roundup Ready®, Bollgard II® and Bollgard® 3 are registered trademarks of Monsanto Technologies LLC, used under licence by Monsanto Australia Ltd. Insect control technology incorporated into these seeds is commercialised under a licence from Syngenta Crop Protection AG. Sicot, Sicala, Siokra and Sipima cotton varieties are a result of a joint venture research program, Cotton Breeding Australia, conducted by CSIRO and Cotton Seed Distributors Ltd (CSD). CSD is a partner in the CottonInfo joint venture, in partnership with Cotton Research Development Corporation and Cotton Australia.